03/23/2023 When it comes to welding, one of the most important steps in the process is prepping the metal. Prepping the metal involves removing any contaminants and ensuring that the surface is clean and ready for welding. Properly prepping the metal can greatly improve the quality of the weld and prevent issues such as porosity, cracking, and weld failure. In this article, we will discuss the steps and strategies for proper weld preparation .

Steps To Proper Weld PreparationStep 1: Remove Any Contaminants

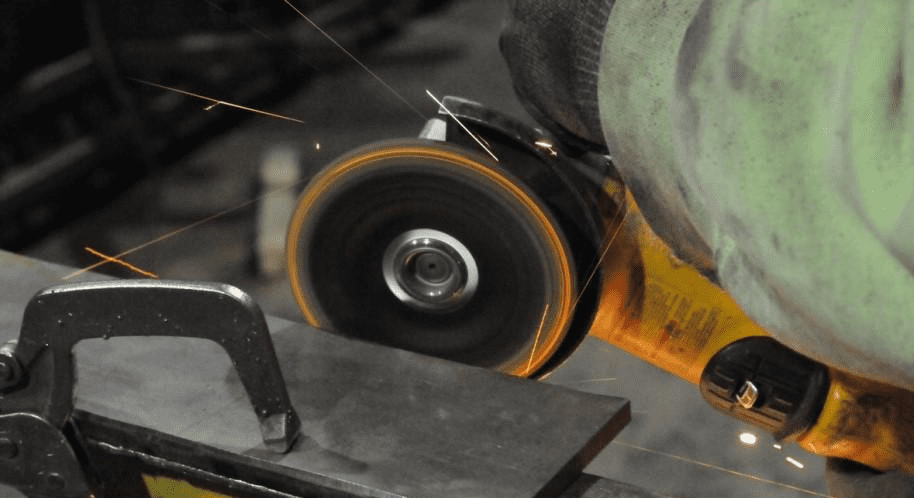

The first step in prepping metal for welding is to remove any contaminants on the surface of the metal. This includes rust, paint, oil, and any other debris that may be present. Failure to remove these contaminants can result in poor weld quality and can even cause the weld to fail. One of the most effective ways is using grinding wheel or using wire brush to remove contaminants. These tools can be used to remove rust, paint, and other debris from the surface of the metal. It is important to wear proper personal protective equipment (PPE), including eye protection and gloves, when using these tools.

Step 2: Clean the Surface

Once any contaminants have been removed, it is important to clean the surface of the metal. This can be done using a solvent such as acetone or alcohol. The solvent should be applied to a clean cloth and used to wipe down the surface of the metal. This will help to remove any remaining contaminants and ensure that the surface is clean and ready for welding. It is important to allow the solvent to fully evaporate before welding to avoid any potential issues.

Step 3: Use a Cutting Wheel

If the metal needs to be cut prior to welding, a cutting wheel can be used to make the necessary cuts. Cutting wheels are a type of abrasive wheel that can be used to cut through metal. These wheels are available in a variety of sizes and can be used with a handheld grinder or a stationary chop saw. It is important to choose the right cutting wheel for the job, as using the wrong wheel can result in poor cuts or even injury. Cutting wheels should be used with proper PPE, including eye protection, gloves, and a face shield.

When using a cutting wheel, it is important to follow these guidelines:

- Choose the right wheel for the job:Cutting wheels come in various diameters, thicknesses, and profiles, and each has its advantages and disadvantages.

It’s crucial to consider the thickness of the material being cut and choose the proper product and tool diameter for the job. Using a 4.5-inch cut off wheel to cut materials that are over 3/8 inch thick is not efficient, as it reduces the number of cuts and the wheel’s life. Moving up to a 6-inch cut off wheel or larger wheel when cutting larger or thicker parts and materials can help tackle the job more efficiently.

The cutting wheel’s profile or type is also important. A Type 1 cutting wheel is flat and efficient for general-purpose cutting, while Type 27 depressed center (raised hub) wheels provide additional offset and are the best choice for flush cutting and rip cutting. Ultra thin

Founded in 2001,BINIC ABRASIVE company is a professional manufacturer for abrasive products and tool accessories, covering cutting disc, grinding wheel ,flap disc, sanding disc ,wire brush and so on for cutting, grinding and polishing industry.We are part of SHANGHAI BINIC INDUSTRY CO.LTD, which is …

Getting the Most Out of Your Angle Grinder: Advice on Grinding, Cutting, and Cleaning